Optimal Timing for Stamped Concrete

Spring offers moderate temperatures ideal for stamped concrete application, ensuring proper curing and adhesion.

Early summer provides warm weather with less rain, suitable for concrete curing and finishing processes.

Fall's cooler temperatures and lower humidity levels help achieve durable, long-lasting stamped concrete surfaces.

Ways to make Stamped Concrete Service work in tight or awkward layouts.

Popular materials for Stamped Concrete Service and why they hold up over time.

Simple add-ons that improve Stamped Concrete Service without blowing the budget.

High-end options that actually feel worth it for Stamped Concrete Service.

Finishes and colors that play nicely with Stamped Concrete Service.

Stamped concrete service involves creating decorative patterns and textures on concrete surfaces to enhance aesthetic appeal. Proper timing ensures optimal curing, adhesion, and durability. Typically, the best periods are during mild weather conditions when temperatures range between 50°F and 85°F. During these times, concrete can cure evenly without issues caused by extreme heat, cold, or excessive moisture. Proper planning around seasonal weather patterns can extend the lifespan and appearance of stamped concrete installations.

Statistics indicate that concrete installed during optimal weather conditions results in fewer cracks and surface defects. Studies show that concrete cured in moderate temperatures has a 30% higher resistance to wear and tear. Additionally, avoiding freezing temperatures during curing prevents surface damage and ensures the integrity of stamped designs. Scheduling during favorable seasons can reduce the need for repairs and maintenance over time.

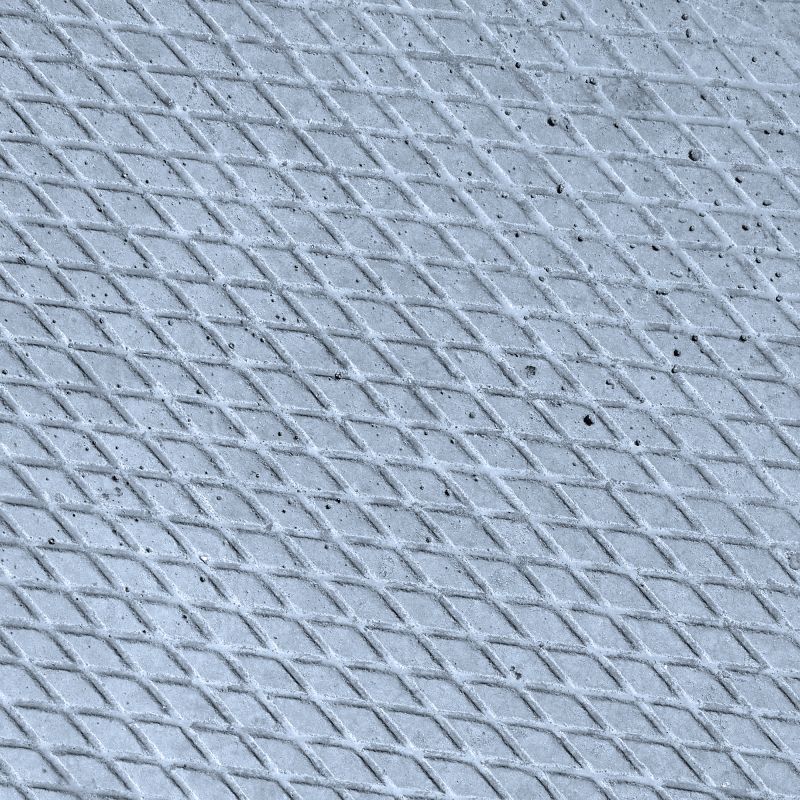

A detailed stamped pattern enhances visual appeal and mimics natural materials like stone or brick.

Color additives are integrated during the stamping process for a customized look.

Textured finishes provide slip resistance and a realistic appearance.

Properly timed stamped concrete offers increased durability for high-traffic areas.

Little measurements that prevent headaches on Stamped Concrete Service day.

A 60-second routine that keeps Stamped Concrete Service looking new.

A frequent mistake in Stamped Concrete Service and how to dodge it.

Small tweaks to make Stamped Concrete Service safer and easier to use.

| Season | Ideal Conditions |

|---|---|

| Spring | Moderate temperatures, low humidity, minimal rain |

| Summer | Warm weather, early summer preferred, avoid extreme heat |

| Fall | Cooler temperatures, low humidity, no frost risk |

| Winter | Not recommended due to freezing temperatures and high moisture |

Scheduling before seasonal weather extremes ensures optimal curing conditions.

Monitoring forecast conditions helps in planning installations during suitable periods.

Proper timing enhances the longevity and aesthetic quality of stamped concrete surfaces.

Choosing the right season for stamped concrete service is crucial for achieving the desired appearance and durability. Consulting with experienced professionals can help determine the optimal timing based on local climate conditions. Proper scheduling minimizes the risk of surface defects, cracking, and color inconsistencies, resulting in a high-quality finished product.

Various patterns and textures can be customized to match aesthetic preferences.

Color can be added during mixing or stamped surface to enhance visual appeal.

Different finishes, including matte or gloss, are available for varied looks.

Lower-waste or water-saving choices for Stamped Concrete Service.

The short, realistic tool list for quality Stamped Concrete Service.

Rough timing from prep to clean-up for Stamped Concrete Service.

Quick checks and paperwork to keep after Stamped Concrete Service.

Examples that show the impact a good Stamped Concrete Service can make.

Interested in stamped concrete services? Filling out the contact form can provide guidance on scheduling and project planning to ensure the best results. Proper timing, combined with professional installation, guarantees a durable, attractive surface that enhances property value.